Bag In Bag Out Housings

Product Details:

- Output Filtered Air

- Energy Consumption Negligible (housing only)

- Frequency 50Hz / 60Hz

- Humidity % Up to 95% RH (non-condensing)

- Features Safe filter change, leak-proof, corrosion-resistant, ergonomic design, maintenance friendly

- Efficiency (%) Up to 99.99%

- Vaccum Range As per application (generally N/A)

- Click to View more

Bag In Bag Out Housings Price And Quantity

- 1 , , Unit

- 48000 INR/Unit

- Tempered glass inspection window (optional)

- Over 10 years under normal operations

- Provision for filter integrity interlock (optional)

- Silicon or Neoprene Gasket for complete leak-proof sealing

- Negative/Positive Pressure Bag-In Bag-Out system with safe change bag

- PAO/DOPE test port integrated

- Smooth powder-coated/SS304 mirror finish for easy cleaning

- DOP/PAO tested as per ISO 14644, EN1822/IEST standards

- Captive swing bolts/lever for tool-free access

- Meets BSC, GMP, and international BIBO guidelines

- 5°C to 60°C

Bag In Bag Out Housings Product Specifications

- Ducted or Plenum connections

- Tool-free filter access, safe bag-out mechanism

- Customizable as per filter

- Bag In Bag Out Filter Housing

- HEPA, ULPA, Pre-Filter (Bag-type)

- Metallic Grey or as required

- Differential Pressure Gauge, Magnehelic Gauge (Optional)

- Up to 25000 CFM or Custom

- Up to 25000 CFM

- Flanged / Gasketed connections

- Ultra-high efficiency particulate removal

- Designed up to 1000 Pa

- Semi-Automatic / Manual

- Floor-mounted / Wall-mounted / Duct-mounted

- Below 65 dB(A)

- Customized as per project specifications

- HEPA/ULPA captured

- Stainless Steel / Mild Steel

- As per application (generally N/A)

- 230V / 415V 50Hz or as required

- Less than 0.01% at outlet

- Pharmaceutical, Healthcare, Biotech, Cleanroom, BSL Labs, Hospitals

- Up to 99.99%

- Up to 95% RH (non-condensing)

- Safe filter change, leak-proof, corrosion-resistant, ergonomic design, maintenance friendly

- As per design (typically not applicable for housing only)

- Varies as per size and configuration

- 50Hz / 60Hz

- Filtered Air

- Negligible (housing only)

- Tempered glass inspection window (optional)

- Over 10 years under normal operations

- Provision for filter integrity interlock (optional)

- Silicon or Neoprene Gasket for complete leak-proof sealing

- Negative/Positive Pressure Bag-In Bag-Out system with safe change bag

- PAO/DOPE test port integrated

- Smooth powder-coated/SS304 mirror finish for easy cleaning

- DOP/PAO tested as per ISO 14644, EN1822/IEST standards

- Captive swing bolts/lever for tool-free access

- Meets BSC, GMP, and international BIBO guidelines

- 5°C to 60°C

Bag In Bag Out Housings Trade Information

- 10 , , Unit Per Week

- 5-15 Days

Product Description

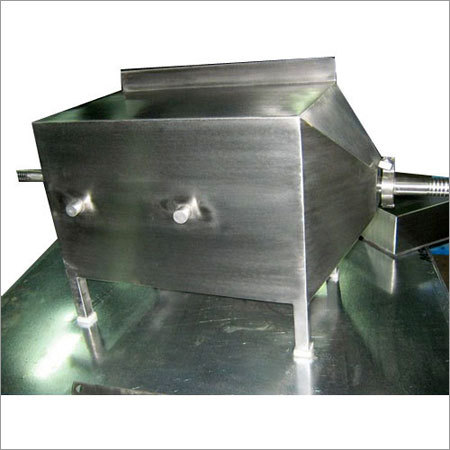

We are recognized as the leading manufacturer, trader and supplier of best quality Bag In Bag Out Housings. Offered products are well designed by making use of supreme quality material and latest techniques keeping in mind the set guidelines of market. This bag in bag out housings helps in expelling strong particles from the liquid effectively furthermore causes high resistance to flow to reduce the liquid pressure. Apart from this, our timeliness in shipment and reasonable pricing structure makes these a preferred choice of the market.

Features:

- Elevated functionality

- Longer service

- Corrosion resistance

- Quality assured

Specifications

- Material: Stainless steel

- Reinforced to With Stand: Up To 20 Inch

- Pressure: 6.0 -10 bar

We give Bag-in and Bag-out Housings at different levels. It is perfect for the anticipation of dangerous airborne particulates, contaminations and residue. These housings ensure site work force and overall population by making a filtration layer and this is likewise demonstrated filtration technique. In this technique the expulsion and transfer of sullied airborne components happens and separation is kept up for clean channel components to keep up the disinfected atmosphere.

Highlights:

- High innovation and propelled machines

- Anticipation from pollution

- Safe and anchored strategy

- Separation of clean components

Utilization: Bag-in and Bag-out Housing has a wide use in clean space to keep up the sound environment, and different assembling units like pharmaceutical and nourishment preparing industry, aviation, semi-conductors, atomic plants and so forth.

Fully Leak-Proof, Safe Filter Change System

The Bag In Bag Out housing utilizes high-grade silicon or neoprene gaskets to achieve a leak-proof seal, critical for environments demanding stringent particulate control. Its tool-free captive swing bolts or lever systems enable quick and safe filter replacement without disassembly, significantly reducing downtime and the risk of contamination during maintenance.

Industry-Compliant Design and Enhanced Safety Features

Tested and certified as per ISO 14644, EN1822/IEST, and GMP guidelines, these housings support essential applications in cleanrooms, BSL labs, and hospitals. Available with optional filter integrity interlocks, tempered glass inspection windows, and integrated PAO/DOPE test ports, the design ensures seamless performance validation and guarantees user safety.

Customizable, Durable Construction for Versatile Applications

Built from premium stainless or mild steel, each system is tailored for the required capacity, layout, and installation mode including wall, floor, or duct mounting. Energy-efficient (housing only), compatible with a range of filter types, and suitable for humidities up to 95% RH, it offers a long service life and adaptability to demanding projects.

FAQs of Bag In Bag Out Housings:

Q: How does the Bag In Bag Out system ensure safe and leak-proof filter changes?

A: The Bag In Bag Out (BIBO) system is engineered with negative/positive pressure safe change mechanisms and uses silicon or neoprene gaskets for a completely sealed environment. Filters can be replaced via a secure, tool-free access method using captive swing bolts or levers, all while a protective bag and sealed connection prevent exposure to contaminants, ensuring operator and environmental safety.Q: What industries and environments are best suited for these BIBO filter housings?

A: These housings are ideal for pharmaceutical manufacturing, healthcare facilities, biotechnology labs, cleanrooms, BSL containment laboratories, and hospitals. Their design meets international standards for high-efficiency particle filtration, leak prevention, and safe maintenance operations, making them suitable for any context requiring ultra-clean air quality.Q: When is leakage and filter integrity typically tested in this equipment?

A: Leakage and filter integrity are verified both during commissioning and routinely as part of scheduled maintenance. The integrated PAO/DOPE test port allows for in-situ testing according to ISO 14644, EN1822, or IEST protocols, ensuring the housing maintains compliance and efficient performance over its lifespan.Q: Where can the BIBO housings be installed and how adaptable are their configurations?

A: Our BIBO filter housings can be installed as floor-mounted, wall-mounted, or duct-mounted systems based on project specifications. They are highly customizable in size, capacity (up to 25,000 CFM), and connection type (flanged or gasketed), accommodating unique layout and filtration demands across a variety of facility types.Q: What is the typical process for changing filters with the safe-change bag-out mechanism?

A: Filter change is performed by detaching the access door using tool-free bolts or levers, enclosing the used filter inside a containment bag, and sealing it for removal. The new filter is then installed, ensuring continual containment and minimal risk of particle release, providing optimal protection for operators and environments.Q: What benefits do optional tempered glass inspection windows and safety interlocks provide?

A: Tempered glass view windows allow visual inspection of the filter and gasket seal without opening the housing, supporting regular monitoring. Optional safety interlocks ensure that filter access is only possible when the system is in a safe state, preventing accidental exposure during maintenance.Q: How long is the expected service life and how is maintenance handled?

A: Designed for over 10 years of service under standard operating conditions, the housings require minimal maintenance due to smooth finishes and tool-free access. Routine filter changes and periodic integrity testing help sustain optimal performance, while robust construction materials ensure long-term reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

GLOWMAX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese